Farmer Stephen Betts shares experience with Dry Misting

May 5, 2021

How Dry Misting helped family farm Laurence J Betts to win multiple ‘Grower of the Year’ Awards

Following the award to L J Betts for UK Grower of the Year 2015 (and UK Edibles Grower of the Year – Vegetables, Gold award), Stephen Betts commented to Contronics Dry Misting, that his decision to install a Dry Misting Hydration System into his new 1000 cu metre cold stores was instrumental in achieving the increased yield and the excellent quality required to win this coveted award.

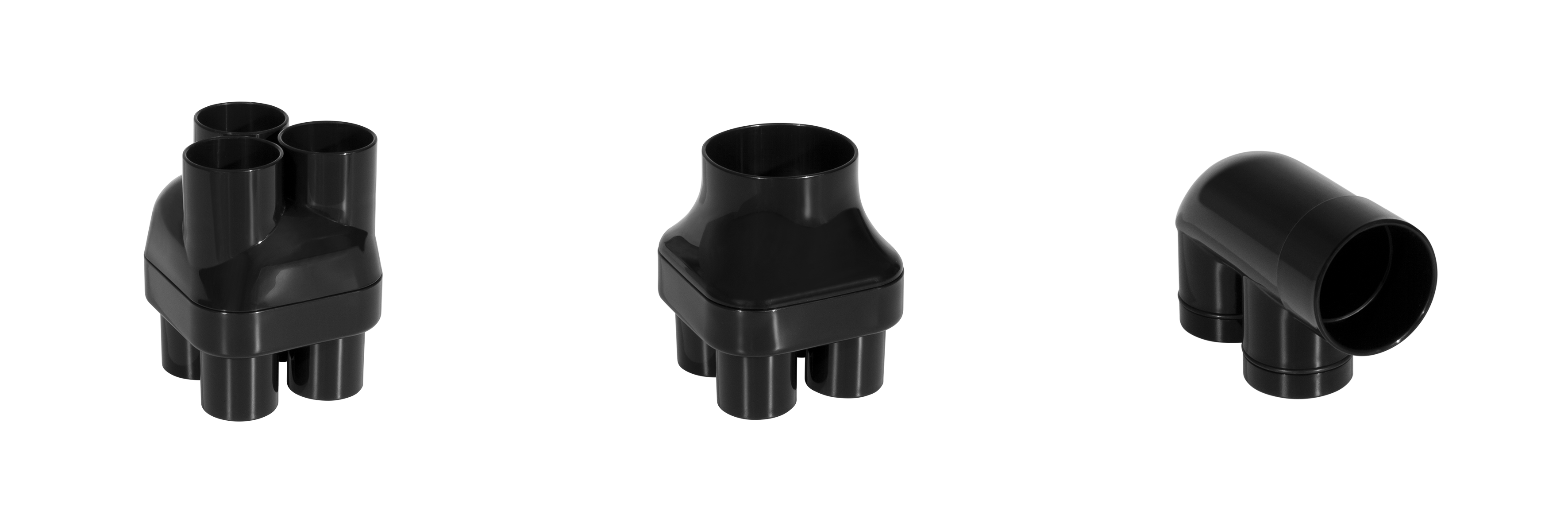

High humidity storage atmosphere with ultra-fine Dry Misting

One obstacle to growth had been the need for a new and larger cold storage facility, which was overcome with the aid of a grant from The Rural Development Programme for England. The grant enabled the business to look forward to further improvements in quality and yield. This was done with the introduction of glycol refrigeration technology which allowed product to be stored at 0.5 – 1°C and in a high humidity atmosphere filled with an ultra-fine, (1-2 micron droplet) Dry Misting.

Stephen Betts commented further,

“Having the Dry Misting system gave us great confidence in our ability to harvest when the product and weather conditions were at their best. It did not take us long to see that ‘Good crops in’ equates to Good produce out’ with Dry Misting.”

Stephen Betts

Reducing harvest costs and labour

Harvesting when the product is ready, and not when orders demand is referred to by Contronics Dry Misting as ‘Strategic Cropping’. This brings with it other advantages such as the opportunity to avoid expensive week-end, early morning or evening harvesting, significantly reducing cost and overcoming issues with staff availability.

“The ability to harvest each field when the product is at its best is a great advantage and not having to harvest when the field and product is wet, reduces wastage and the need to dry the product. Also avoiding the extremes of hot weather reduces cooling costs and the need to resort to vacuum cooling, furthering de-hydration.”

Gentle cooling of crops harvested in good conditions saves money and labour, whilst enabling the product to re-hydrate to full turgidity when necessary in a few hours, then maintaining that almost indefinitely.”

Stephen Betts

Waste through dehydration is all but eliminated and enables Contronics Dry Misting customers to deliver consistent high quality and all round better product from stabilized stock rather than being rushed off the field to meet demand.

The Dry Misting system allows harvested produce to naturally hydrate, extending the life of tender leaf from 1-2 days after harvest (with standard DX cooling) to 4-7 days using DX combined with Dry Misting. The result is similarly impressive for salad and brassica, with life being extended from 10 days up to 21 days.

Dry Misting technology – and the game-changing Strategic Cropping that it enables – smoothens the peaks and troughs of a turbulent and ever-changing season, maximizing yield, quality and as a result, financial return.

Gerelateerde artikelen

Press

Press

Dutch Article: Dry Misting succesful on German retail market

October 10, 2023 – Distrifood.nl publishes a Dutch article about the increasing popularity of Dry Misting among German retailers. “Na succesvolle implementatie bij Nederlandse ketens als Albert Heijn, PLUS en Jumbo, omarmen nu ook Duitse supermarkten zoals EDEKA en REWE Dry Misting. Gebauer’s E-Frische Center in Göppingen, Duitsland, nam de technologie in augustus 2021 in

Lees verder Press

Press

Article: EDEKA retailer shares experience with Dry Misting

March 31, 2023 – Manfred Gebauer noticed multiple improvements in his EDEKA store (Göppingen, DE) after the installation of Dry Misting. Read more about his experience in this (German) interview with Lebensmittel Zeitung: Click here to read

Lees verder News

News

Albert Heijn Reaches Dry Misting Milestone

ESM Magazine – March 18, 2023 Dutch retailer Albert Heijn has equipped more than 700 stores with ‘Dry Misting’ technology from Contronics. Dry Misting creates a fine layer of pure mist in the air around fresh produce on display without soaking the products or the shelves. The evaporation of the mist cools and protects the

Lees verder